/ Smart manufacturing / In control / Workload planning

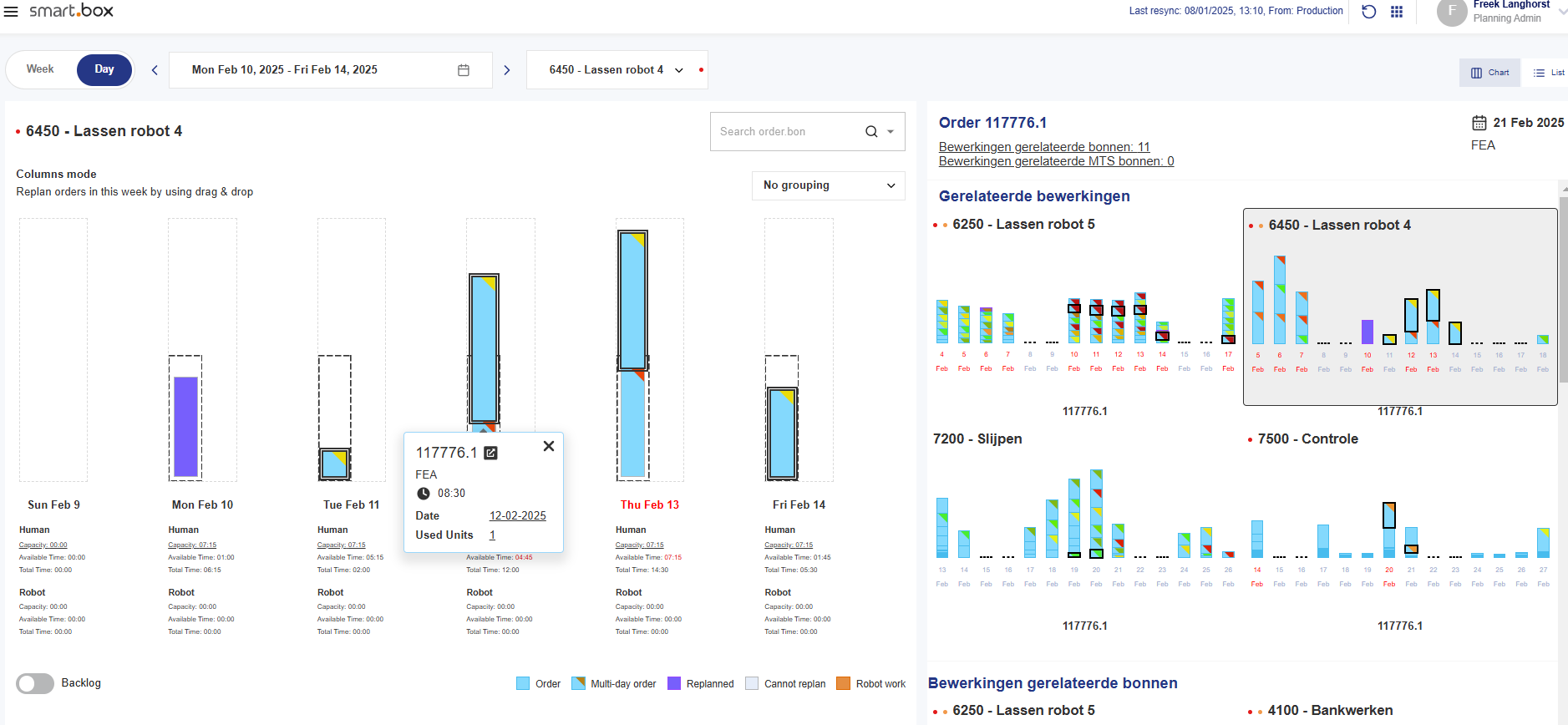

Is it possible to save time in planning and rescheduling orders? Absolutely – we can do it much more efficiently! Imagine visually and interactively planning and replanning your orders and capacity. This can be done manually, allowing you to instantly see the impact on both the current operation and all related activities (for the current order and its dependencies).

With our AI solution, orders can be automatically rescheduled, ensuring that all orders are perfectly planned and capacity is fully optimized. This not only saves significant time for both planning and production teams but also saves a lot of time to focus on resolving bottlenecks and driving process improvements.

You plan orders outside the ERP system and “simulate” the planning actions. If everyone agrees to the changes, the changes are automatically implemented in ERP at the push of a button.

- All production orders are accurately scheduled, including any backlog orders.

- Our application considers all variables, such as suborders, outsourcing, and orders that should never be rescheduled.

- Plan visually yourself and then sync it back to the ERP…

- …or opt for our AI solution that automatically schedules all orders correctly.

- The smart.planning application is compatible with any ERP system and can be optionally integrated with the smart.box shop floor solution or any other system.

- Historical data offers valuable insights into bottlenecks and their causes.

“Thanks to the use of the smart.planning application, our production planning is largely automated.”

Peter Quist

Manager Finance and IT – BOZ Group

“Thanks to the smart.planning application, our production planning is largely automated, taking into account our business rules regarding priorities and capacities. This allows us to focus on exceptions and further optimisation of production and planning. Thanks to the extensive logging of the tool, we gain insight into the bottlenecks in the production process and the structural points for improvement.

The team at smart.box has excellent expertise and proactively thinks along to realize the desired solution. The personal attention and open communication are greatly appreciated in this regard.”

Working Digitally

Every employee always receives only the correct order information in a user-friendly way.

Monitor and control

You want to monitor daily operations and make immediate adjustments as needed.

Transparency in the office

Gain insight into how much your support and service departments can contribute to value-added activities.

Workload planning

A reliable output starts with the right input. Seek a smart solution that can continuously monitor and (re)schedule 1000+ orders.

Data-driven stand-up meeting

Always up-to-date operational data for Safety, Quality, Delivery, Cost and People (SQDCP).

What you measure, you know

Let's integrate all production and logistics resources to enhance the order flow.

Pull planning

Prevent overproduction and high WIP in assembly and job shop environment.

Assembly

Prevent overproduction and high WIP in assembly and job shop environment.

Zero mistakes

Let’s optimize processes in a way that continuously minimizes the chance of errors

OEE measurement

Maximizing machine productivity starts with understanding the biggest disruptions and downtime.

Collaboration between human and machine

Let's integrate all production and logistics resources to streamline and enhance the order flow.